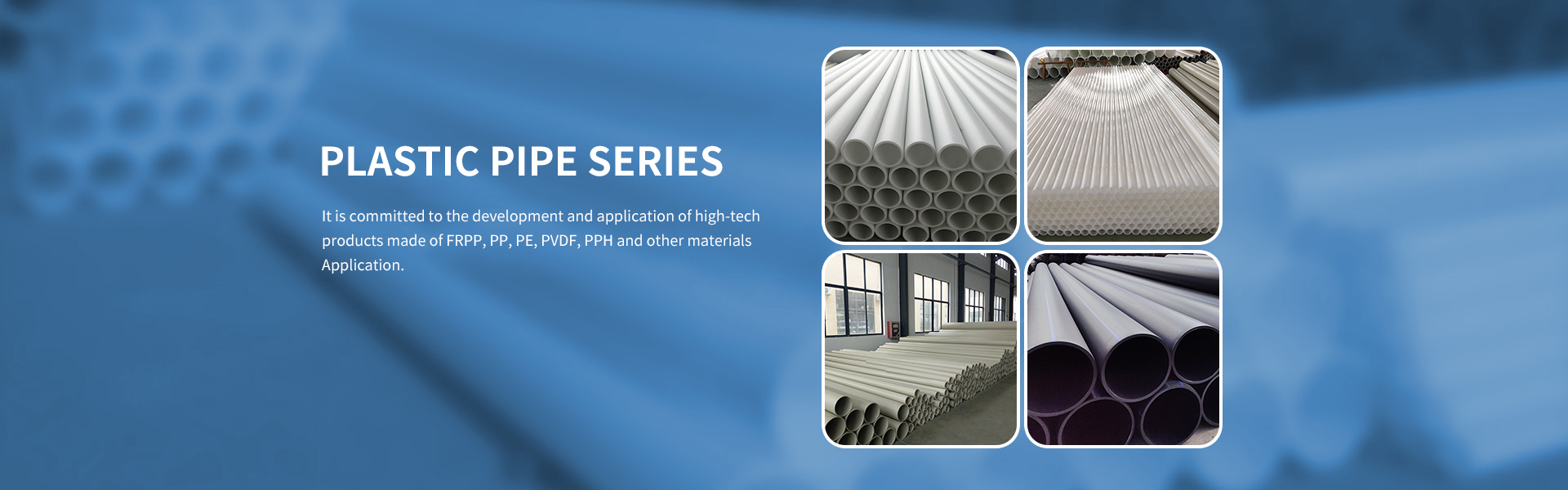

1、 Materials

PPH tube is made of high density polypropylene (PPH) as raw material and antioxidant, anti ultraviolet agent and pigment as the main body. PPH pipe has the characteristics of good heat setting, high temperature resistance, good chemical resistance, creep, high tension, good insulation, insoluble in organic solvents, non dry crack and non-toxic. It is applicable to chemical plants, electronic semiconductor plants, pharmaceutical plants, sewage treatment plants and other industries. It is widely used in high acid-base chemical product transportation system, pure water transportation system, drinking water transportation system, sewage and wastewater transportation system, environmental engineering and general pipeline system, Telecom Optical Cable transportation and piping system.

Welding machines and tools

PPH pipe welding is used for hot-melt welding. Various specifications of hydraulic or manual plastic pipe hot-melt machines are used. Taking the hydraulic plastic pipe hot melt welder as an example, the welding is mainly divided into three parts: welding control platform, welding operation platform and tool rack.

Prepare for welding

The pipe cutter (pipe cutter), acetone and cleaning cloth matched with the pipe type shall keep the surrounding environment clean and free of dust, and the ambient temperature shall not be lower than 0 ℃.

4、 Hot melt welding

Welding is mainly divided into 7 steps: cutting, preheating, matching, heating, welding, cooling and inspection.

1. Use a special tool to cut the pipe according to the required size. Be careful not to insert the pipe into the blade when cutting the pipe. Do not push too fast, or the blade will be damaged. When the cutter is difficult to rotate, reverse the cutter, take out the blade and run the line again.

2. Adjust the preheating pressure to the welding pressure with the hydraulic regulating valve. Adjustment method: lock the heating pressure safety valve, push the hydraulic rod forward and observe the pressure gauge. If the required pressure is not reached, loosen the heating safety valve to reduce the pressure gauge display to zero, readjust the hydraulic control valve, and then lock the heating safety valve until the pressure reaches the required pressure. Use the temperature setting panel on the welder control platform to set the temperature of hot-melt welding, and control the temperature of the heating plate to match the melting of the welding surface. Red is the set temperature and green is the current temperature. When the red light on the panel jumps to the green light, hot melt welding can be carried out. The melting temperature of PPH is generally set between 195 ℃ and 205 ℃.

3. (1) select a suitable die and fix the welding section on the console with a wrench;

Note: when fixing, tighten the fastening screws at both ends of the fixture in turn to avoid irregular pipe sections; When the hydraulic control lever is pulled back, the distance between the two sections shall not be less than the thickness of the electric cutting machine; When the 40 ~ 50mm pipe section is long, the welding surface of each pipe section shall protrude from the overall level of the fixture.

(2) Push the hydraulic rod to the and pair the two pipe sections. Visually check the wrong opening on the welding surface and touch the bottom of the welding with your hand to make the two joints horizontal. If it fails to meet the requirements, adjust the screws at both ends to make the welds level without staggering;

(3) Visually inspect the joint of two welding surfaces to achieve the joint without obvious gap; If any, grind with an electric cutter. Place the cutting machine on the operating frame, start the cutting machine, and another person controls the hydraulic push rod to press the pipe section to the cutting machine according to the set pressure; Visually cut the weld until the weld is flush. Retract the hydraulic clamp, take out the cutting machine and put it back into the tool holder;

Note: after hydraulic clamping, do not stop the cutting machine in a hurry. Turn the cutter several times before taking it out. It can make the welding surface smooth and prevent the appearance of cross section.

(4) Clean the welding surface and clean the welding surface with a clean cloth dipped in a small amount of acetone.

4. Heat

Remove the heating plate that has reached the required temperature from the tool holder. Place it on the operation frame and press the hydraulic fixture to the welding side to make the pressure reach the required welding pressure. When the hot-melt flanging of the welding surface reaches 1mm, loosen the heating safety valve and relieve the heating pressure. After waiting for a period of time, the hot-melt butt joint requirements on the weld surface can be met.

Note: the heating plate must be placed vertically.

中文(简体)

中文(简体)