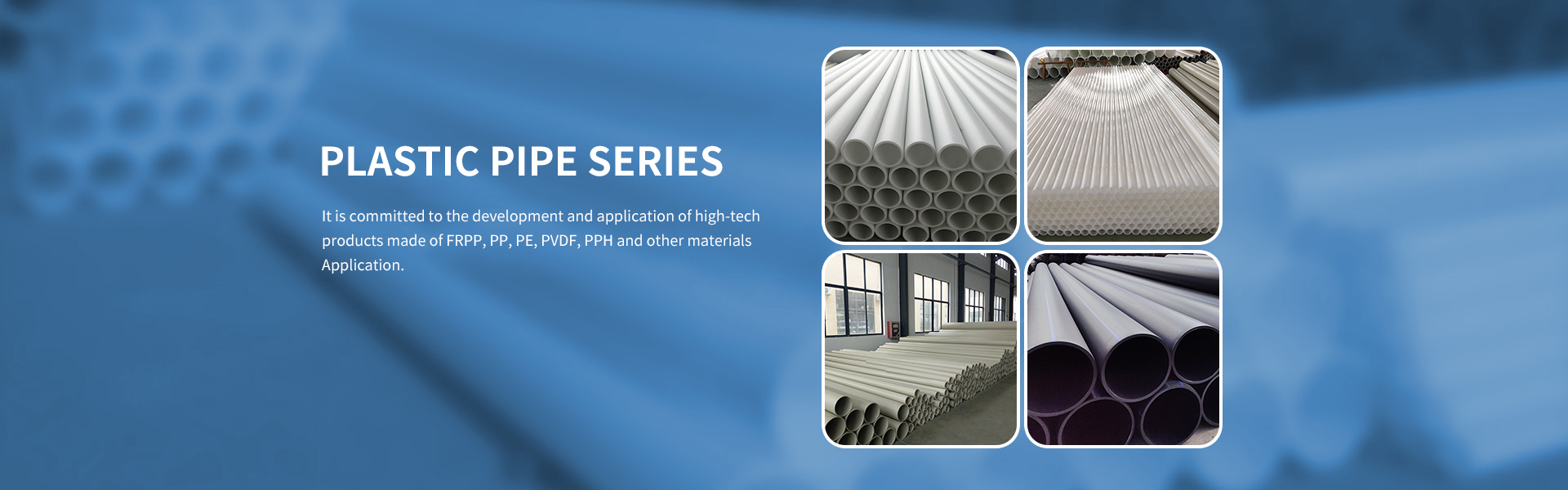

In recent years, FRPP pipe has risen in the pipe industry, and its superior performance and convenient and fast connection mode are loved by the majority of users. Therefore, people often ask what is the difference between FRPP pipe and HDPE pipe? What are the advantages of the two pipes?

1 what is FRPP pipe?

Glass fiber reinforced polypropylene pipe (FRPP pipe) is made of glass fiber modified polypropylene treated with coupling agent. According to hg20539-92 standard, the specification is DN 15, DN 1500 mm, and the nominal pressure is 0.4-1.0 MPa. Corrosion resistant, high temperature resistant, high pressure resistant, hygienic, non-toxic and recyclable. It is suitable for conveying corrosive liquid (such as acid-base solution) and municipal water supply and drainage system. It has excellent impact and tensile strength, light weight and convenient installation and maintenance. The existing hot air welding connection, hot melt connection and flange connection are widely used in chemical industry, chemical fiber, chlor alkali, dye, water supply and drainage, food, medicine, sewage treatment, electrolysis and other industries.

Long service life: FRPP pipe can be safely used for more than 50 years under rated temperature and pressure.

Excellent corrosion resistance: FRPP pipe can resist the corrosion of most chemicals and can withstand the corrosion of high concentration acid and alkali in the range of 1-14 in a large range.

High stiffness: FRPP pipe is not easy to deform due to the addition of glass fiber reinforced materials.

Heat resistance, thermal insulation and energy saving: the service temperature of FRPP pipe is 95 ℃, and the thermal conductivity of this product is only 1 / 200 of that of steel pipe, which has good thermal insulation performance.

Reliable connection performance: the strength of hot-melt joint of FRPP pipe is higher than that of pipe body, and the joint will not break due to soil movement or load.

Good construction performance: the weight of FRPP pipe is light, the flange connection mode is adopted, the installation personnel are reduced, the installation time is accelerated, and the comprehensive project cost is low.

2 what is HDPE pipe?

HDPE pipe high density polyethylene, English name is "high density polyethylene", referred to as "HDPE". HDPE is a high crystallinity, non-polar thermoplastic resin. The appearance of the original HDPE is milky white and the sheet is translucent. In industry, polyethylene and chemicals have excellent life resistance. Some types of chemicals produce chemical corrosion, such as corrosive oxidants (concentrated nitric acid), aromatic hydrocarbons (xylene) and halogenated hydrocarbons (carbon tetrachloride). The polymer is non hygroscopic and has good water vapor resistance. It can be used for packaging. High density polyethylene (HDPE) has good electrical properties, especially the high dielectric strength of insulation, which is very suitable for wires and cables. Medium and high molecular weight brands have excellent impact resistance at room temperature, even at - 40F low temperature.

HDPE pipeline is mainly used in municipal engineering water supply system, building indoor water supply system, outdoor buried water supply system and industrial water pipes in residential areas, plant buried water supply system, old pipeline maintenance, water treatment engineering pipeline system, gardens, irrigation and other fields.

To sum up, the materials of the two pipes are different, and the connection methods are also different. FRPP pipes prefer to complete all processes in the factory to reduce the workload on the construction site. At the same time, HDPE pipe also has groove connection mode. When HDPE grooved pipe is used on site, the manufacturer shall be equipped with a special slotting machine, and the workers shall learn to use it. At present, FRPP pipe has been used in high-rise buildings.

中文(简体)

中文(简体)