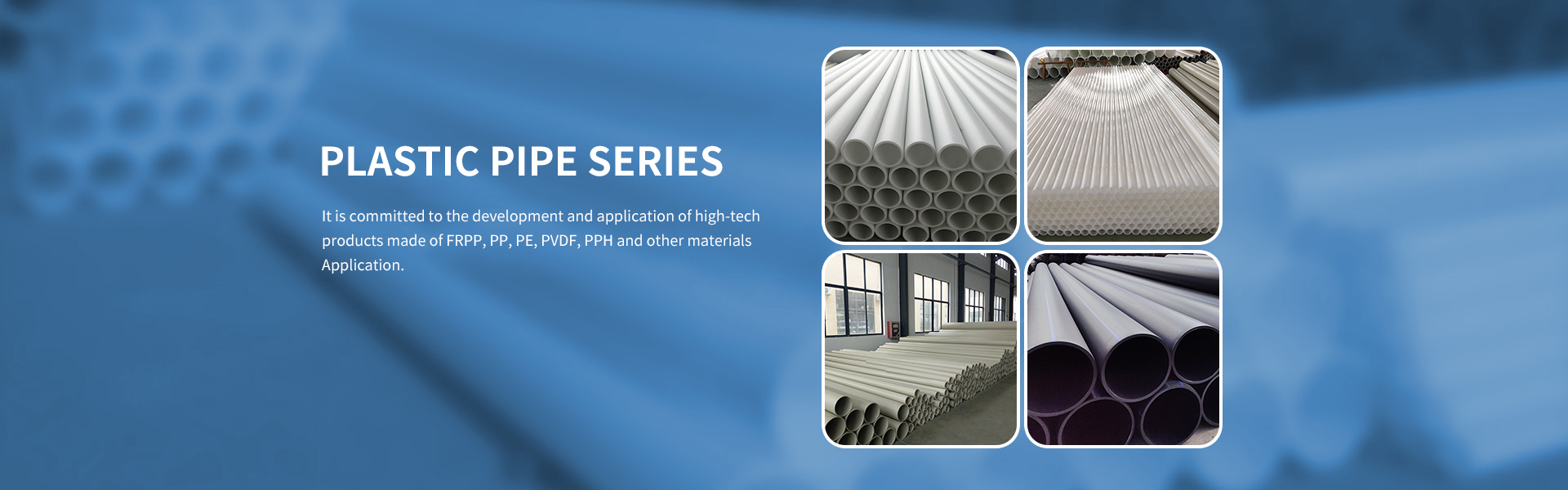

There are many installation methods of polypropylene pipes, which are mainly selected according to the needs of the project. At present, the market share of PP pipe fittings in the construction industry should rank in the top four. After all, many hotels, shopping malls, buildings, residential buildings and other buildings pay great attention to the mute effect of pipes. Then the superior mute effect of PP pipe will be effectively utilized. Today, Yitong pipe will take you to understand the common installation methods of PP pipe and the installation skills of PP mute pipe in life.

Installation method of polypropylene silent pipe

First, a special tool must be used for cutting to ensure that the section is perpendicular to the axis. It is recommended that the spacing between two sets of socket flexible joints should not exceed 3M, and the length can be adjusted according to the socket depth. In addition, the length of the pipe outlet inserted into the bottom of the pipe fitting shall not exceed 8mm in summer and 12mm in winter.

2. Electric heating wire welding method of polypropylene pipe

Remove the oxide scale on the surface of the pipe, insert the pipe fitting with electric heating element of corresponding specification, connect the rated current to the heating element for a period of time, heat the polypropylene material at the connection between the pipe fitting and the pipe, melt each other, and turn off the power supply to form a solid and indivisible interface.

Three. Butt welding method of polypropylene silent pipe

Firstly, flatten the pipe end, place the heating plate between the aligned pipes or between the pipes and pipe fittings, set the heating temperature, turn on the control power supply, after heating for a period of time, pull out the heating plate, then connect the two ends firmly, and then press them together to form a high-strength trapezoidal joint, and the interface strength is the same as the body material.

Because the hot-melt connection method does not need any additional materials, and the connection part can be melted into a whole, which can achieve body strength and good connection effect, the hot-melt connection method is a common connection method for polypropylene pipes. However, when using the hot melt bonding method, the following points should be noted

① The hot melt tool can be operated only when the power is turned on and the working temperature indicator is on;

② When cutting the pipe, the end face must be perpendicular to the pipe axis. Special scissors or pipe cutting machine are generally used for pipe cutting, and sharp hacksaw is used when necessary.

③ Pipes and fittings of the same brand shall be used for hot-melt connection. Pipes with similar performance can be constructed only after passing the test.

④ Pipes and fittings shall be placed on the construction site for a certain time before connection to make the temperature of pipes and fittings consistent

⑤ Special heating tools and pipe fittings shall not be used according to different heating methods.

中文(简体)

中文(简体)