With the continuous improvement of people's quality of life, water safety has attracted more and more attention, so the selection of water transmission pipeline is particularly important. Today, let's introduce what types of water pipe materials are there?

Water supply pipeline, as the name suggests, is the pipe of water supply or other water transmission projects. It is different from the drainage pipe. It needs to bear a certain water supply pressure. Therefore, it is more strict in material selection. At present, the water supply pipeline on the market can be divided into two types according to material, one is metal pipe, the other is non-metal pipe.

Metal pipes are generally used outdoors, including steel pipes and ductile iron pipes. Firstly, the steel pipe is divided into seamless steel pipe and welded steel pipe. Our ordinary galvanized steel pipe also belongs to metal steel pipe. It is only galvanized on ordinary steel pipe to play the role of corrosion resistance. Its production method can be welding or seamless production, depending on its production process, but on the other hand, it is brittle and hard, heavy weight and high construction requirements!

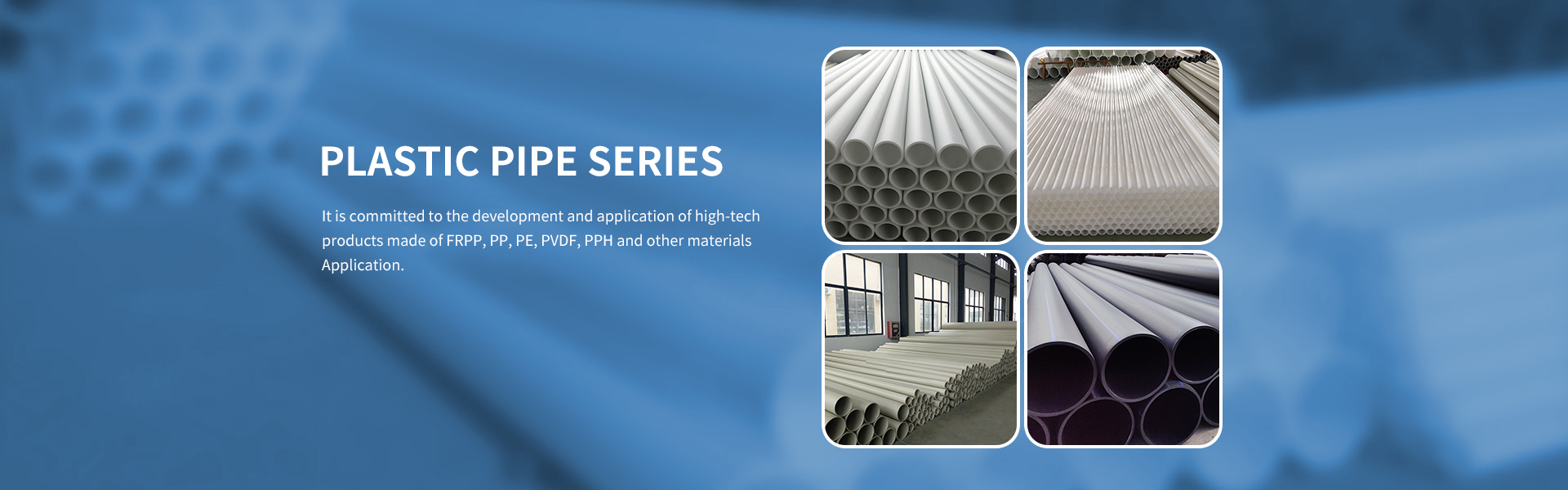

Non metallic pipes have a wide range of applications and a wide variety, including reinforced concrete pipes, asbestos cement pipes, FRP pipes, etc. Today, we focus on hdep mute tube in plastic tube. PE pipe is widely used in many fields.

Simultaneous interpretation of water supply pipeline and gas pipeline are two major application markets. A good pipeline should not only have good economy, but also have a series of advantages such as reliable interface, impact resistance, crack resistance, aging resistance, corrosion resistance and so on. Compared with traditional pipes, yetun HDPE pipes have the following advantages:

Reliable connection: the polyethylene pipeline system adopts electrothermal fusion connection, and the strength of the joint is higher than that of the pipe body. Good low-temperature impact performance: the low-temperature embrittlement temperature of polyethylene is very low, and it can be used safely in the temperature range of - 60-60 ℃. Good stress cracking resistance: HDPE has low notch sensitivity, high shear strength and excellent scratch resistance, and its ability to resist environmental stress cracking is also very outstanding. Good chemical corrosion resistance: HDPE pipeline can resist the corrosion of a variety of chemical media, and the chemicals in the soil will not cause any degradation to the pipeline. Polyethylene is an electrical insulator, so it will not rot, rust or electrochemical corrosion; In addition, it does not promote the growth of algae, bacteria or fungi. Aging resistance and long service life: polyethylene pipes containing 2-2.5% uniformly distributed carbon black can be stored outdoors or used for 50 years without being damaged by ultraviolet radiation. Easy handling: HDPE pipe is lighter than concrete pipe, galvanized pipe and steel pipe. It is easy to operate and install. The lower demand for manpower and equipment means that the installation cost of the project is greatly reduced. Easy installation: HDPE pipe has a variety of construction processes. In addition to the traditional excavation methods, a variety of new non excavation technologies such as pipe jacking, directional drilling, lining and pipe blasting can also be used, which is the choice for some places where excavation is not allowed. Therefore, the application field of HDPE pipe is more extensive

中文(简体)

中文(简体)